Silver tin oxide electrical contact( AgSnO2 ) is environmental protection and non-toxic, with excellent anti fusion welding and arc ablation resistance performance. In general speaking, under the condition of larger current, AgSnO2 has better ability of arc ablation resistance than AgCdO, and under the lamp or capacitive load, AgSnO2 showed a stronger ability to resist current shock than AgCdO, AgNi.

Silver Tin Oxide Electrical Contact

Electrical Contact factory, more than 10 years manufacture experience, attained ISO9001, work on OEM and ODM projects.

1. Introduction of Silver tin oxide electrical contact

Silver tin oxide( AgSnO2 )electrical contactare environmental protection and non-toxic, with excellent anti fusion welding and arc ablation resistance performance.

In general speaking, under the condition of larger current, AgSnO2 has better ability of arc ablation resistance than AgCdO, and under the lamp or capacitive load, AgSnO2 showed a stronger ability to resist current shock than AgCdO, AgNi.

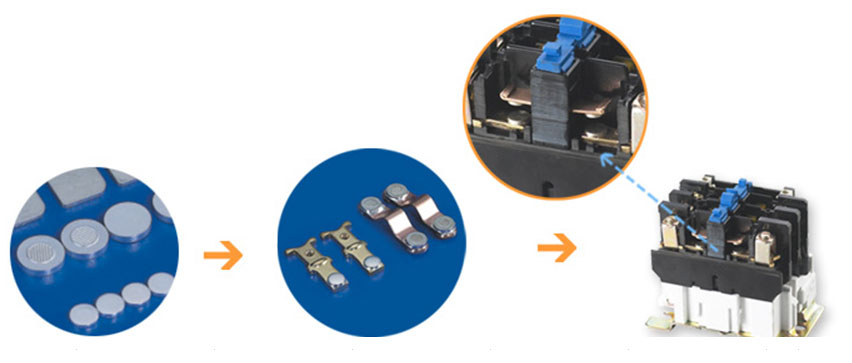

2. Application of Silver tin oxide electrical contact

AgSnO2 electrical contacts are widely used in large capacity contactor, power relay, medium and small capacity of low voltage circuit breaker, and automobile electronicsetc.

3. Main Materials for Silver tin oxide electrical contact

Main face materials: AgSnO2 8, AgSnO2 10, AgSnO2 12, AgSnO2 15, AgSnO2 20

Main base materials : Cu, CuNi

|

Category |

Density g/cm3≥ |

Electrical conductivity .cm≤ |

Hardness soft HV≥ |

Tensile strength soft MPa≥ |

|

AgSnO2 92/8 |

10 |

2.08 |

57 |

225 |

|

AgSnO2 90/10 |

10 |

2.13 |

62 |

230 |

|

AgSnO2 88/12 |

9.9 |

2.22 |

67 |

235 |

|

AgSnO2 85/15 |

9.68~9.96 |

2. 56 |

95 |

250 |

|

AgSnO2 80/20 |

9.65~9.95 |

2.66 |

97 |

275 |

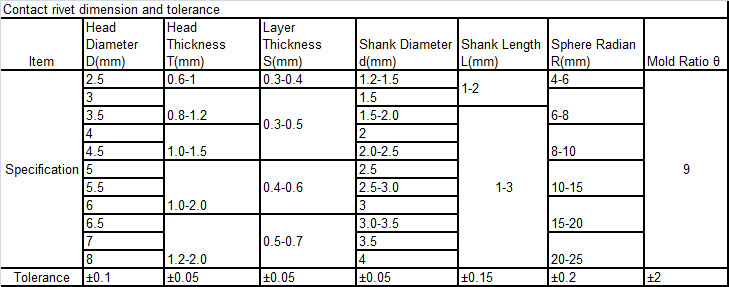

4.Specification of Silver tin oxide electrical contact

Dimensions can be customized

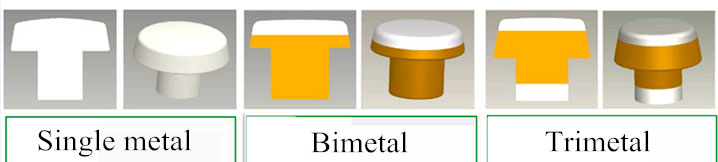

5. Product types for Silver tin oxide electrical contact

Round head rivets, Flat head rivets, Bimetal rivets, Tri-metal rivets and special type

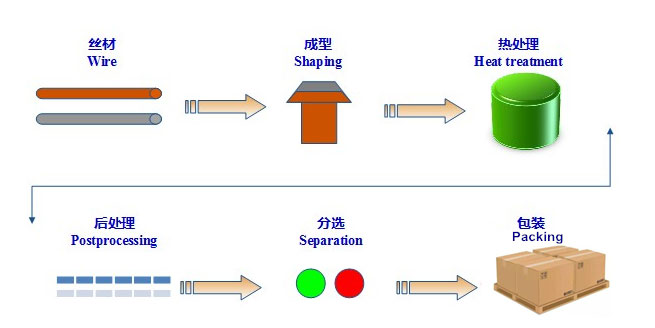

6. Process of SnO2Silver tin oxide electricalcontact

7. Manufacture plant ofSilver tin oxide electrical contact

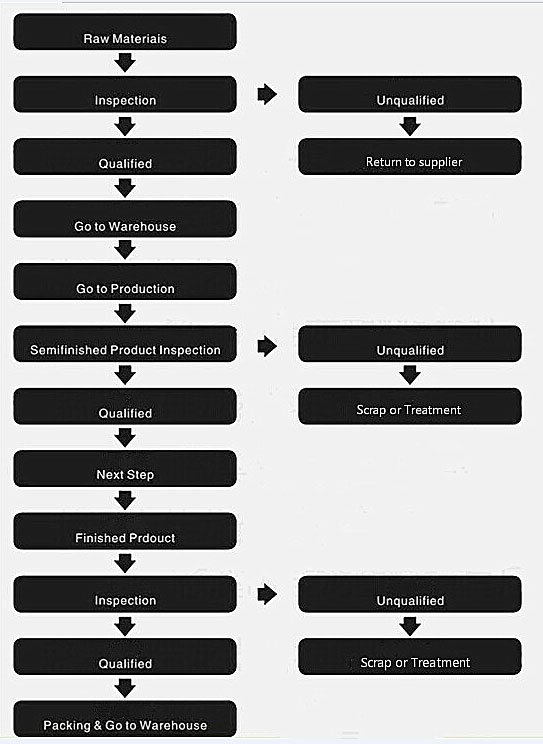

8. Quality control flow chart of Silver tin oxide electrical contact

9. Packing and shipping forSilver tin oxide electrical contact

Packing:

First put 500-5000 pcs into small plastic bags or vacuum plastic bags, then in separated small carton box, at last Into hard cardboard box.

Shipping:

We

will choose the best way according to customer’s requests.

1.

By Air, to the indicated airport.

2. By Express (FedEx, UPS, DHL, TNT,EMS), to the indicated address.

2.By Sea, to the indicated sea port.

10.FAQ

Q1. Can you help customers for designing products?

A1. We can help customers to design the best products to achieve both good function and costs saving according to their application.

Q2. Can you help us to choose suitable material?

A2. We can recommend the most suitable material according to your application.

Q3. What kind of electrical contact material you can provide?

A3. We can provide fine silver(Ag) , AgNi, AgCdO, AgSnO2, AgZnO, AgSnO2ln2O3, AgC , AgWC , AgW , CuW etc

Q4. Can you provide free samples?

A4. If we have the right or similar sizes in stock, we can send you for free.

Q5. How do you control quality?

A5. We produce strictly according to customer’s drawings and requests, here are strict control plan in every process, full check of each parts, strive to provide customer 100% quality products, ROHS/SGS test report, material certificate are available.