H63 Brass Strip Coil with copper content 63%,has a very similar performance with H65,It also has a high strength and plasticity, can well withstand with cold and hot pressure processing.

H63 Brass Strip Coil

Brass factory, more than 10 years manufacture experience, attained ISO9001, work on OEM and ODM projects..

1. Introduction of the H63 brass strip coil

H63 / C2720 / CuZn37 brass with copper content 63%,has a very similar performance with H65,It also has a high strength and plasticity, can well withstand with cold and hot pressure processing.

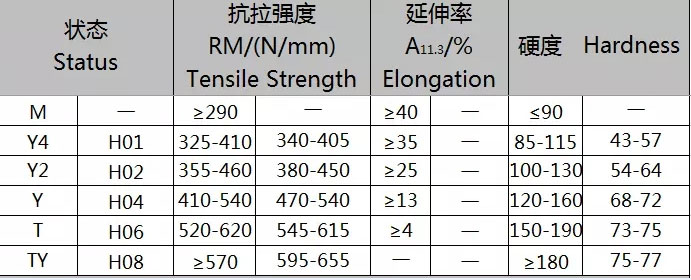

2. Grade and temper for H63 brass strip coil

Grade: C2720, C27200, CDA272, C272, CZ108, H63, CuZn37

Temper: O(M), 1/4H(Y4), 1/2H(Y2), H(Y), HH(T)

Different countries’Standard comparison table of brass

|

GB |

DIN |

EN |

ISO |

UNS |

JIS |

||

|

H96 |

CuZn5 |

2.0220 |

CuZn5 |

CE500L |

CuZn5 |

C21000 |

C2100 |

|

H90 |

CuZn10 |

2.0230 |

CuZn10 |

CW501L |

CuZn10 |

C22000 |

C2200 |

|

H85 |

CuZn15 |

2.0240 |

CuZn15 |

CW502L |

CuZn15 |

C23000 |

C2300 |

|

H80 |

CuZn20 |

2.0250 |

CuZn20 |

CW503L |

CuZn20 |

C24000 |

C2400 |

|

H70 |

CuZn30 |

2.0265 |

CuZn30 |

CW505L |

CuZn30 |

C26000 |

C2600 |

|

H68 |

CuZn33 |

2.0280 |

CuZn33 |

CW506L |

CuZn35 |

C26800 |

C2680 |

|

H65 |

CuZn36 |

2.0335 |

CuZn36 |

CW507L |

CuZn35 |

C27000 |

C2700 |

|

H63 |

CuZn37 |

2.0321 |

CuZn37 |

CW508L |

CuZn37 |

C27200 |

C2720 |

3. Chemical composition of H63 brass strip coil

Chemical composition

Cu :62.0~65.0

Zn:balance

Pb:≤0.08

P:≤0.01

Fe:≤0.15

Sb :≤0.005

Bi:≤0.005

inpurity:≤0.3

4. Dimension and tolerance of H63 brass strip coil

Specification(mm)

Thickness

Width

0.08~0.12

≤300

>0.12~0.15

≤600

>0.15~<0.50

≤600

0.5~3.0

≤1000

5. Characteristics of H63 brass strip coil

|

Properties |

Metric |

Imperial |

|

Density |

8.47 g/cm3 |

0.306 lb/in3 |

|

Melting point |

904°C |

1660°F |

Mechanical

properties

6. Application of H63 brass strip coil

C2720 H63 CuZn37 is used in all kinds of deep drawing and bending manufacturing parts, stamping parts, springs, screens, heat etc.

7. Manufacture plant of H63 brass strip coil

8. Tests and inspection for H63 brass strip coil

Test instrument : Metallographic Microscope; Digital Light Processor; Strength Tester; Hardness Tester.

9. Quality certificate for H63 brass strip coil

10. Packing and shipping for H63 brass strip coil

Packing:

First wrapped by anti-rust paper, second wrapped by plastic film, then packed by wooden box or wooden pallet ..

Shipping:

We

will choose the best way according to customer’s requests.

1.

By Air, to the indicated airport.

2. By Express (FedEx, UPS, DHL, TNT,EMS), to the indicated address.

2. By Sea, to the indicated sea port.

11.Questions and Answers

a1. Do you have ISO certificate?

Yes, we obtained ISO9001

a2. How long is your delivery time for H63brass strip?

If the master coil is available, 3-7 days do slitting will be ready , if not, will need 20-25 days for new production.

a3. Can you help us to choose suitable material?

Yes, we can recommend the most suitable material according to your application.

a4. How do you control quality?

We produce strictly according to customer’s drawings and requests, here are strict control plan in every process, full check of each parts, strive to provide customer 100% quality products, ROHS/SGS test report, material certificate are available.

a5. Do you provide sample? Free or charge?

Yes, if the sample in stock available, free of charge, if not, need to charge some mfg cost.