C7701 C7521 Nickel Silver strip alloys, also called Copper-Nickel-Zinc alloys, which has good formability, good corrosion and tarnish-resistance performance, and this alloy has the pleasing silver-like color.

C7701 C7521 Nickel Silver Strip

Nickel silver alloy factory, more than 10 years manufacture experience, attained ISO9001, work on OEM and ODM projects..

1. Introduction of the C7701 C7521 Nickel Silver strip

C7701 C7521 Nickel Silver alloys, also called Copper-Nickel-Zinc alloys, which has good formability, good corrosion and tarnish-resistance performance, and this alloy has the pleasing silver-like color.

2. Grade and temper for C7701 C7521 Nickel Silver strip

Grade: UNS.C77000, CDA770, CuNi18Zn27, JIS C7701, BZn18-27 ,CW410J

UNS C75200, CDA752 , CuNi18Zn20, JIS C7521, BZn18-20, CW409J

Temper: O(M), 1/4H(Y4), 1/2H(Y2), H(Y), HH(T)

3. Chemical composition of C7701 C7521 Nickel Silver strip

C7701 Chemical Composition:

Cu: 54.0-58.00%

Ni: 16.5.00-19.5%

Fe: 0.25% Max.

Pb: 0.05% Max.

Mn: 0.50% Max.

Zn: Balance

C7521 Chemical Composition:

Cu: 62.0-66.00%

Ni: 16.5.00-19.5%

Fe: 0.25% Max.

Pb: 0.05% Max.

Mn: 0.50% Max.

Zn: Balance

|

Material |

Grade |

Chemical Composition |

||||||||

|

|

|

Be |

Ni |

Co |

Sn |

Mn |

Fe |

Pb |

Cu |

|

|

Nickel silver |

C7701 |

~ |

16.5-19.5 |

~ |

~ |

0~0.5 |

≤0.25 |

≤0.05 |

54-58 |

|

|

C7521 |

~ |

16.5-19.5 |

~ |

~ |

0~0.5 |

≤0.25 |

≤0.05 |

62-66 |

||

4. Dimension and tolerance of C7701 C7521 Nickel Silver strip

|

Thickness mm |

Width mm |

||||||||||

|

≤200 |

>200~400 |

>400~600 |

>600~1000 |

||||||||

|

Thickness tolerance / ± mm |

|||||||||||

|

Ordinary Level |

Ordinary Level |

Ordinary Level |

Ordinary Level |

||||||||

|

0.10~0.20 |

0.010 |

0.015 |

0.015 |

— |

|||||||

|

>0.20~0.30 |

0.015 |

0.020 |

0.020 |

— |

|||||||

|

>0.30~0.50 |

0.020 |

0.025 |

0.030 |

0.050 |

|||||||

|

>0.50~0.70 |

0.030 |

0.035 |

0.040 |

0.060 |

|||||||

|

>0.70~1.10 |

0.040 |

0.045 |

0.050 |

0.070 |

|||||||

|

>1.10~1.50 |

0.050 |

0.055 |

0.060 |

0.080 |

|||||||

|

>1.50~2.50 |

0.055 |

0.060 |

0.080 |

0.100 |

|||||||

5. Characteristics of C7701 C7521 Nickel Silver strip

|

Mechanical Properties |

||||

|

Alloy No |

Quality Grade |

Tensile Strength (Kgf/mm) |

Elongation % |

Hardness Test HV |

|

C7521 |

O |

≥38.5 |

≥20 |

~ |

|

1/2H |

45~58 |

≥5 |

120~180 |

|

|

H |

55以上 |

≥3 |

≥150 |

|

|

C7701 |

1/2H |

55~66 |

≥8 |

150~210 |

|

H |

64~75 |

≥5 |

180~240 |

|

|

EH |

72~82 |

~ |

240~260 |

|

|

SH |

78~88 |

~ |

230~270 |

|

6. Application of C7701 C7521 Nickel Silver strip

C7701 C7521 Nickel Silver strip is mainly used in Liquid crystal oscillator component housing, medical machinery, slides for potentiometers, precision instruments, architecture, wind instruments, etc.

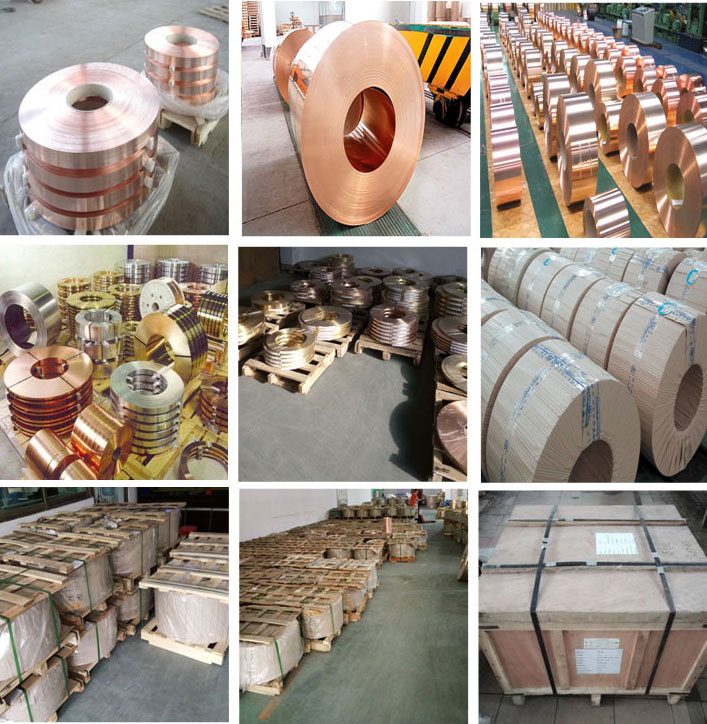

7. Manufacture plant of C7701 C7521 Nickel Silver strip

8. Tests and inspection for C7701 C7521 Nickel Silver strip

Test instrument : Metallographic Microscope; Digital Light Processor; Strength Tester; Hardness Tester.

9. Mill certificate forC7701 C7521 Nickel Silver strip

10. Packing and shipping for C7701 C7521 Nickel Silver strip

Packing:

First wrapped by anti-rust paper, second wrapped by plastic film, then packed by wooden box or wooden pallet ..

Shipping:

We

will choose the best way according to customer’s requests.

1.

By Air, to the indicated airport.

2. By Express (FedEx, UPS, DHL, TNT,EMS), to the indicated address.

2. By Sea, to the indicated sea port.

11.Questions and Answers

a1. Do you have ISO certificate?

Yes, we obtained ISO9001

a2. How long is your delivery time forNickel Silver strip?

If the master coil is available, 3-7 days do slitting will be ready , if not, will need 20-25 days for new production.

a3. Can you help us to choose suitable material?

Yes, we can recommend the most suitable material according to your application.

a4. How do you control quality?

We produce strictly according to customer’s drawings and requests, here are strict control plan in every process, full check of each parts, strive to provide customer 100% quality products, ROHS/SGS test report, material certificate are available.

a5. Do you provide sample? Free or charge?

Yes, if the sample in stock available, free of charge, if not, need to charge some mfg cost.